- Hydrogen Rising

- Posts

- Cleanergy Solutions unveils Namibia’s pioneering hydrogen hub

Cleanergy Solutions unveils Namibia’s pioneering hydrogen hub

Dear subscriber, this is a prototype. Please help us with feedback. Just press reply.

Namibia-based green hydrogen developer Cleanergy Solutions has launched the country’s first integrated green hydrogen hub. Part of the Hydrogen Dune Project, the facility comprises a solar-powered, off-grid electrolyser and a refuelling station for hydrogen-powered vehicles. It also features a Hydrogen Academy for training. |

The plant integrates the full hydrogen value chain from production to distribution and end-use, making it one of the most complete hydrogen hubs on the continent.

It prioritises skills development through the Hydrogen Academy, a dimension often overlooked as similar hubs in Africa focus mainly on production while neglecting downstream use and training.

Our take: The hub builds on Namibia’s growing credibility as a leading player in innovative, value-chain-wide hydrogen development……..Read more (2 min)

While North Africa may not have the financial muscle of Gulf countries to drive large-scale industrialisation, Soumya Ranjan Pradhan suggests that by 2030, the region will emerge as Europe’s premier green steel partner. North Africa, he notes, compensates for its financial limitations with strategic geography and abundant resources. |

Mr Pradhan is the Head of Metals Division at BDB India Private Limited. He is an expert in the global steel industry with 14+ years of experience across the entire value chain.

He argues that North Africa’s proximity to European markets, combined with significant iron ore reserves and massive renewable energy potential, positions the region to supply low-carbon steel and green hydrogen at scale.

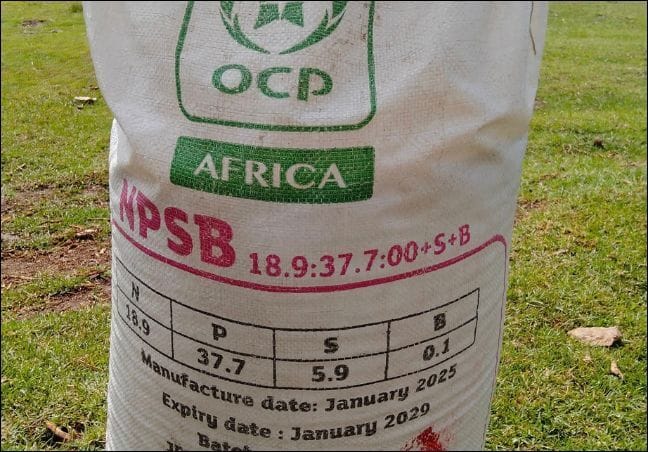

Morocco-based OCP Group, a leading producer of phosphate-based fertilisers, has signed an agreement with U.S. climate-tech company Peregrine Hydrogen Inc. to co-produce clean hydrogen alongside sulphuric acid using Peregrine’s electrolyser technology. The innovation is expected to lower fertiliser production costs. |

Unlike conventional electrolysis that splits water into hydrogen and oxygen, Peregrine’s technology routes the oxygen stream into reactions that generate sulfuric acid, a compound OCP already consumes in massive volumes for fertiliser production.

Peregrine’s electrolyser decarbonises phosphate fertiliser by producing renewable hydrogen and sulphuric acid on-site, replacing fossil-fuel hydrogen and lowering the fertiliser’s carbon footprint without changing existing production processes.

Our take: OCP's backing signals confidence in early-stage technology, highlighting its potential to become a game-changer in decarbonising fertiliser production……Read more (2 min)

________//___________

Namibia’s Prime Minister fuels the country’s first green hydrogen-powered bus

Events

🗓️ Register for the World Power-to-X Summit in Morocco (October 1)

🗓️ Sign up for the 3rd Hydrogen in Africa conference in Egypt (October 28)

🗓️ Network at the West Africa Clean Energy Conference in Nigeria (November 11)

🗓️ Attend the Africa Energy Expo in Rwanda (November 25)

Jobs

🧑🚒 Work as Senior Energy Engineer at Arup (South Africa)

🧑🚒 Coordinate just energy transition activities at GIZ (South Africa)

🧑🚒 Guide just energy transition activities at GIZ (South Africa)

🧑🚒 Be the next Senior Energy Researcher at Pele Energy (South Africa)

Various

🗺️ Fraunhofer IEEE launches Kenya’s PtX Atlas

🤝 Namibia discusses green hydrogen partnership with the EU

🎊 Morocco clears preliminary phase of ‘Chbika 1’ green hydrogen project

🏢 South Africa launches temporary office to oversee green hydrogen rollout

🎉Namibia’s Duares Green Hydrogen Village enters phase 2

✍️ Morocco signs land agreements for green hydrogen projects

💹 EU to fund Ignite GH2 project to promote green hydrogen skills

Seen on LinkedIn

Dr. David Novak, a freelance professor says, “A major barrier for clean hydrogen today is that dirty methods based on fossil fuels are just so much cheaper than cleaner ones.”